Curriculum Options

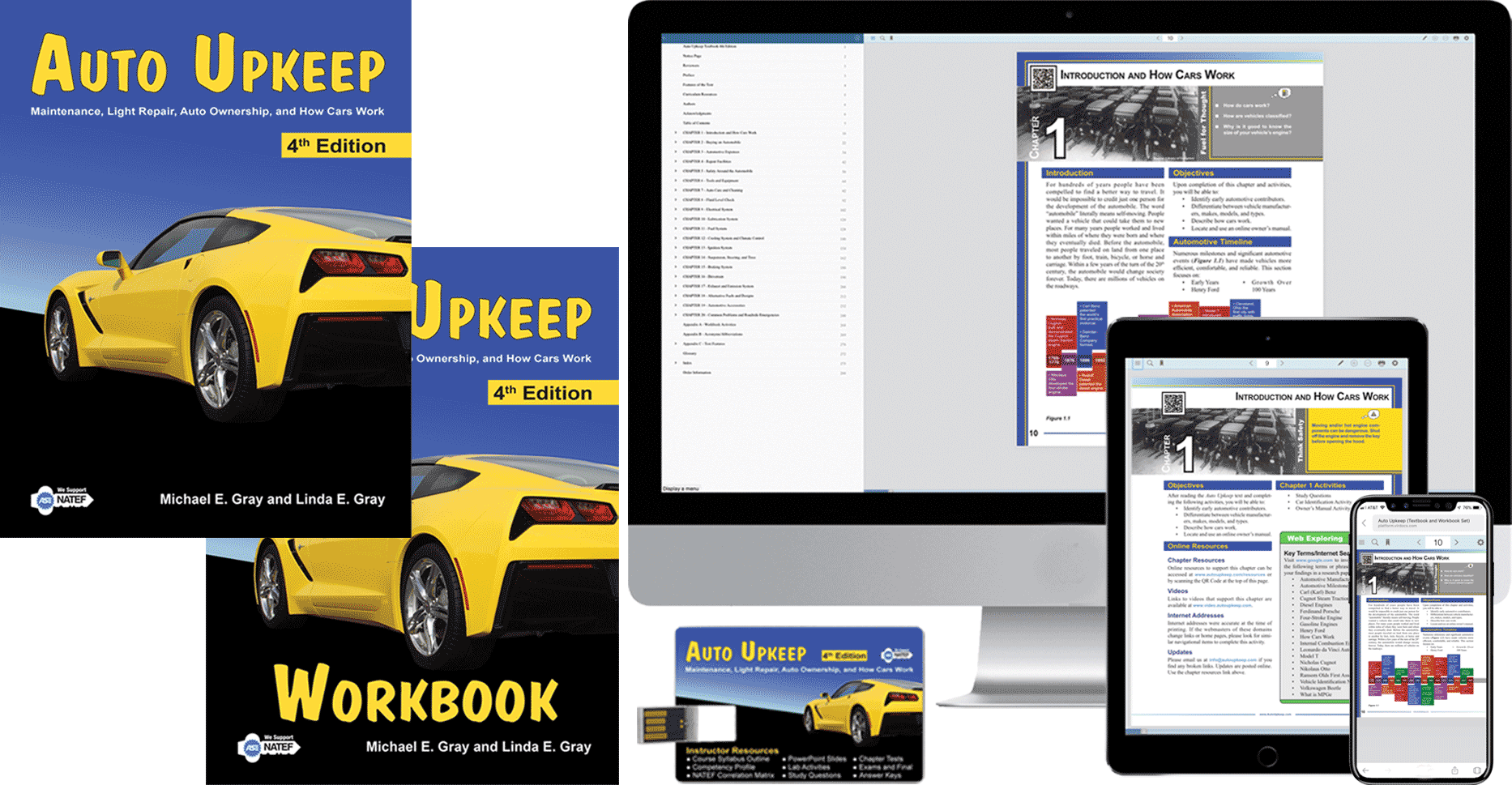

Auto Upkeep Textbook

• 288 FULL COLOR Pages

• 20 Easy-to-Read Chapters

• Over 700 Illustrations

• Hardcover and Paperback

Auto Upkeep Workbook

• 176 FULL COLOR Pages

• 40 Hands-on and Internet-based Activities

• Over 250 Illustrations

Instructor Resource USB

• Course Syllabus Outline

• ASE Ed (NATEF) & TEKS Correlations

• PowerPoints Presentations

• Lab Activities

• Study Questions

• Chapter Tests (LMS Compatible)

• Exams/Final (LMS Compatible)

• Answer Keys

Auto Upkeep eBook (RedShelf eReader)

• Access on Any Device with Internet

• Rent or Buy

• Highlight and Take Notes Digitally

• Enhanced Navigation

• Keyword Search

• Create Flashcards and Study Guides

• Collaborate with Peers

Auto Upkeep Online Academy

• Access on Any Device with Internet

• All 21 Courses

• All 41 Activities

• Graded Tests

• Interactive Lessons

• Gamified Design

• Connected Community

• Collaborate in Groups

Reviews

Choose Your Classroom

Automotive Programs

Auto Upkeep has been adopted by over 500 automotive programs. Universities, colleges, technical schools, and high schools choose Auto Upkeep for Introduction to Automotive classes. Learn More

Homeschools & Co-ops

The Auto Upkeep Homeschool Curriculum Kit was designed so YOU can teach your teens about basic car care, maintenance, repair, auto ownership, and how cars work. Individual kits and co-op packages are available. Learn More

DIYers

Do you want to learn how cars work? Auto Upkeep will help you become confident in accomplishing simple, but important, preventative measures on your vehicle – all while saving money. Learn More

Driver's Ed

Auto Upkeep is a perfect fit to teach in combination with driver’s education classes. As students learn the skills of safe driving, it is also important for teens to understand how to choose a quality repair facility, buy a car, handle roadside emergencies, and how a car works. Learn More

Adult & Continuing Ed

Adult and continuing education programs can benefit by offering “Car Care” classes. The most expensive item people will have after a home is an automobile. Learning the basics helps drivers become confident automobile owners. Learn More

Afterschool Programs

Are you looking for a hands-on, engaging curriculum for teens? The Auto Upkeep Curriculum works well in afterschool programs providing teens with opportunities to learn about basic car care, maintenance, repair, and ownership. Our curriculum has all the resources needed to help students become responsible auto owners. And get this…it is FUN and PRACTICAL! Learn More

Clinics & Workshops

Have you considered running a Car Care Clinic, Know Your Car event, or Automotive Basics class? An educated automotive consumer is a win-win for the driver and the auto shop. Learn More

Scouts, Trail Life, & 4-H

Auto Upkeep is a fun way for groups to discover how to choose a quality repair facility, buy a car, handle roadside emergencies, diagnose common problems, and communicate effectively with technicians – all while saving money. Learn More

Popular Pricing Options

Paperback Set

Great Value-

Paperback Textbook

-

Paperback Workbook

Hardcover Set

Most Durable-

Hardcover Textbook

-

Paperback Workbook

Print + eBook

Hardcover Set + eBook Access-

Hardcover Textbook

-

Paperback Workbook

-

eTextbook

-

eWorkbook

eBook Access

Rent or Buy Options-

eTextbook

-

eWorkbook

Meet the Authors

Hi! We are Mike and Linda Gray, the authors of Auto Upkeep. We believe there is a better way for drivers to connect with their automobiles, a safer, less expensive way in which drivers can prepare for and avoid the unexpected. We are extremely passionate about helping others, and our mission is to provide the tools for drivers to achieve self-reliance and confidence. Automobiles are integral to our way of life, yet often one of the least understood technologies, Mike and I see that as an opportunity to share what we have learned.

We have dedicated the last 19 years to helping drivers and are eager to continue simplifying automobile ownership for every driver with our Auto Upkeep curriculum and resources. Discover more about us.

The Gray Family

Still Have Questions?

Check out the FAQs.

Why is it important to maintain the oil in an engine?

Learn about checking and changing engine oil in Chapter 10.

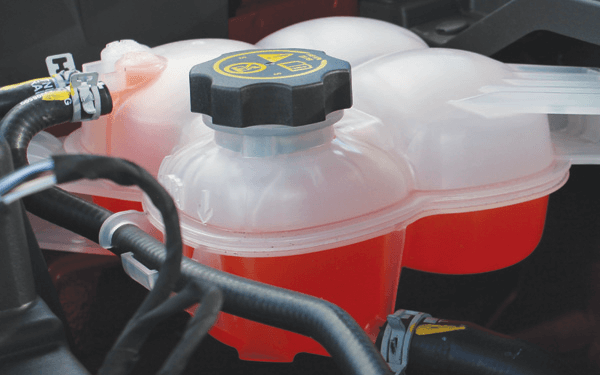

What should you do if your engine starts to overheat?

Learn about engine coolant and the cooling system in Chapter 12.

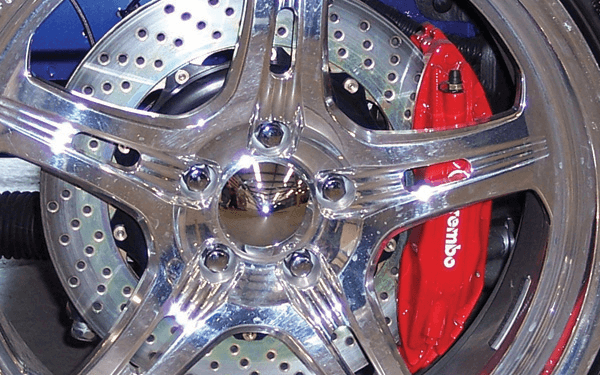

How do you know when your brake pads need replacing?

Learn about brake pads and the braking system in Chapter 15.